Unveiling the Skyward Shift – How Automation and Robotics are Revolutionizing Air Cargo Warehousing

In the ever-evolving world of air cargo logistics, the warehouse has traditionally been the unsung hero. It’s the place where the intricate ballet of packing, sorting, and shipping takes place. But in recent years, a remarkable transformation has been unfolding, and it’s all thanks to the rise of automation and robotics in air cargo warehousing. Buckle up as we embark on a journey to explore how technology is reshaping the very foundations of air cargo logistics.

The Age of Automation Dawns

Historically, air cargo warehouses were bustling hubs of human activity. Workers would scurry to load and unload goods, sort packages, and ensure timely departures. While this human touch was crucial, it came with limitations – the constraints of physical stamina, the risk of injuries, and the challenges of scaling operations.

The Solution: Automated Warehousing

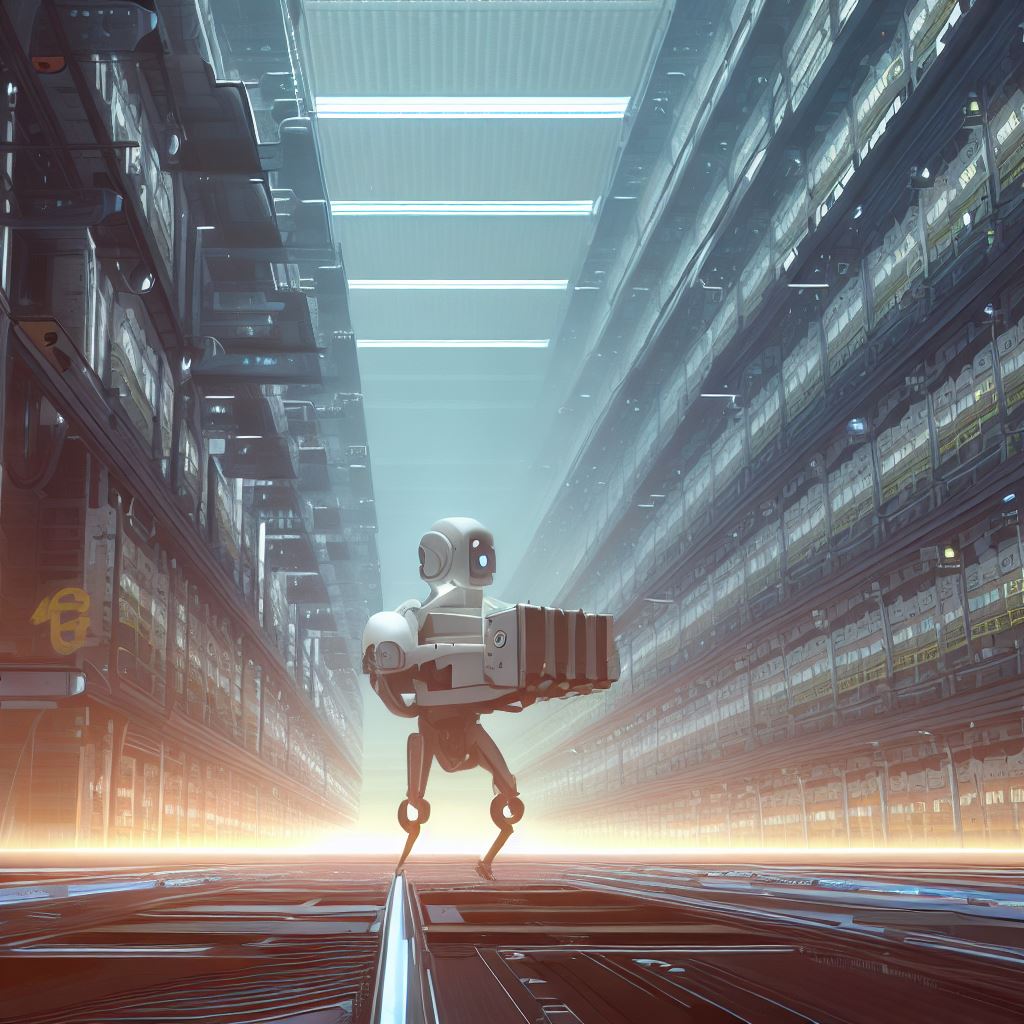

Enter automation. Today, air cargo warehouses are undergoing a profound shift, transitioning from manual labor to automated systems. These cutting-edge warehouses are equipped with a symphony of technology, including conveyor belts, autonomous robots, and AI-powered sorting systems.

Use Case 1: Sorting and Routing Efficiency

Imagine a massive air cargo hub, a hive of activity with packages arriving from all corners of the globe. In this automated wonderland, packages are swiftly identified, scanned, and sorted by machines. Autonomous robots navigate the vast warehouse floors, carrying packages to their designated locations with precision and speed that human workers simply can’t match.

Use Case 2: Inventory Management

Keeping track of inventory is a critical aspect of air cargo warehousing. Automation extends its hand here as well. Drones equipped with cameras and sensors patrol the warehouse, performing inventory checks and reporting discrepancies in real-time. This ensures that every package is accounted for and in the right place.

Real-World Success: DHL’s Robotic Revolution

One standout example of this transformative shift is DHL, a global leader in logistics. DHL’s warehouses now feature an army of autonomous robots known as “EffiBOTs.” These robots zip around warehouses, picking up and delivering packages with remarkable efficiency. The result? Faster processing times, reduced labor costs, and fewer errors.

The Future: Uncharted Skies of Innovation

As we peer into the future of air cargo warehousing, the potential for further innovation is boundless. Automation and robotics will continue to evolve, with advanced AI systems optimizing warehouse operations in real-time. 3D printing may even enable on-demand manufacturing within warehouses, reducing the need for lengthy supply chains.

A New Horizon for Air Cargo

In conclusion, the advancements brought about by automation and robotics in air cargo warehousing are truly revolutionary. These remarkable technologies are not intended to replace humans, but rather to enhance their capabilities and improve efficiency. The warehouses of tomorrow will be more intelligent, faster, and incredibly adaptable, ushering in a new era of air cargo logistics.

As we continue our journey through the ever-changing landscape of the air cargo industry, stay tuned for more stories that unveil the cutting-edge innovations and emerging trends shaping its future. The possibilities are limitless, and the future holds great promise for air cargo logistics.